Our 503B Facility

Leading the outsourcing facility industry

Expanding Access

Founded

Square Feet

Sterile Products

Empower Pharma503B outsourcing facility

Our FDA-registered 503B outsourcing facilities, fully compliant with cGMP standards, were meticulously constructed to meet the industry's most rigorous quality benchmarks. At Empower, we employ cutting-edge pharmaceutical technologies to efficiently manufacture custom compounded medications on a large scale, serving doctors' offices, pharmacies, and various healthcare institutions across the nation. As a nationally licensed facility, our commitment to quality and accessibility is integral to every facet of our operations.

ADVANCED METHODOLGYQuality assurance and advanced protocols

Innovation

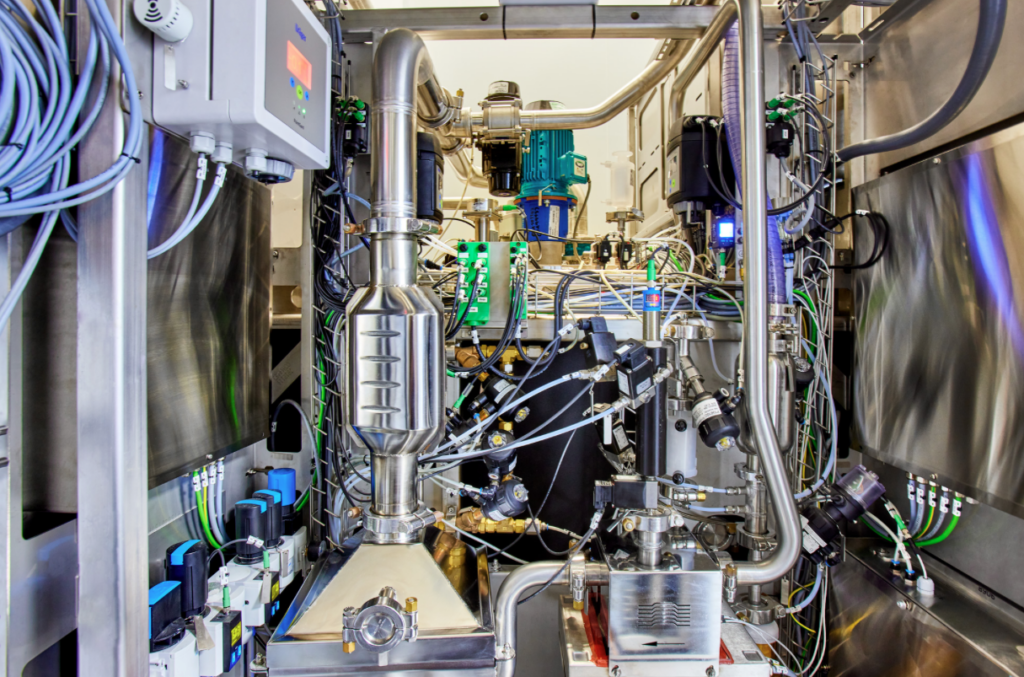

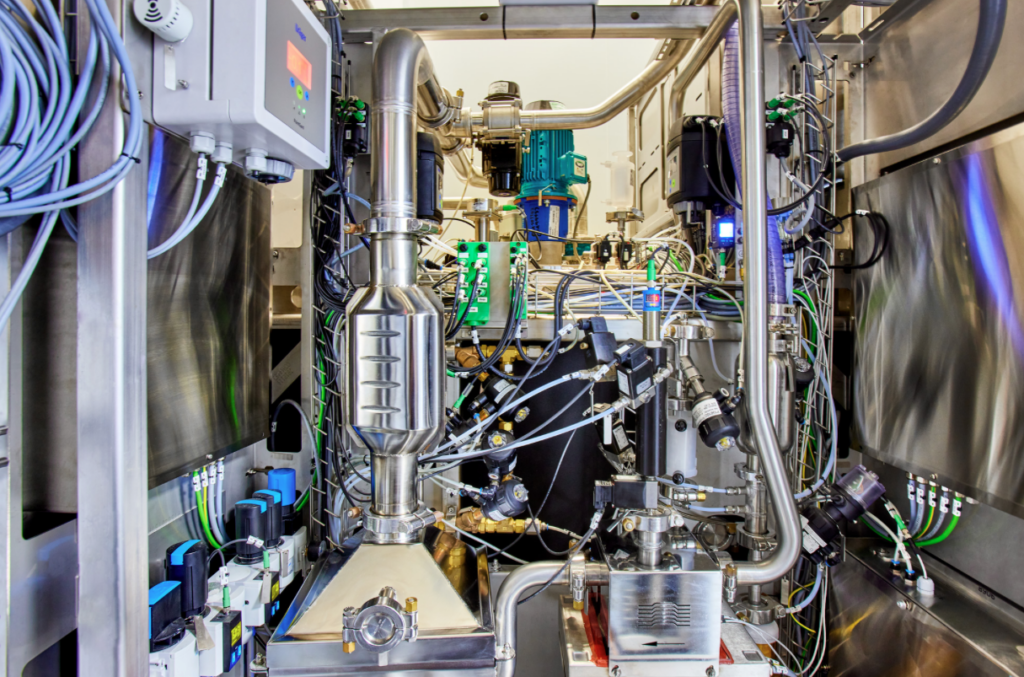

As an engineer-led company, our primary focus is on developing systems and pioneering technology to streamline manufacturing and quality processes. Specialized equipment plays a crucial role in ensuring quality assurance and maintaining consistency in production at Empower.

High Volume Production

We have strategically invested in our capacity to produce large batches using highly efficient equipment. Precision in any method necessitates the use of the most advanced technology, and we are committed to this standard to further broaden access to custom formulations for a growing patient populations.

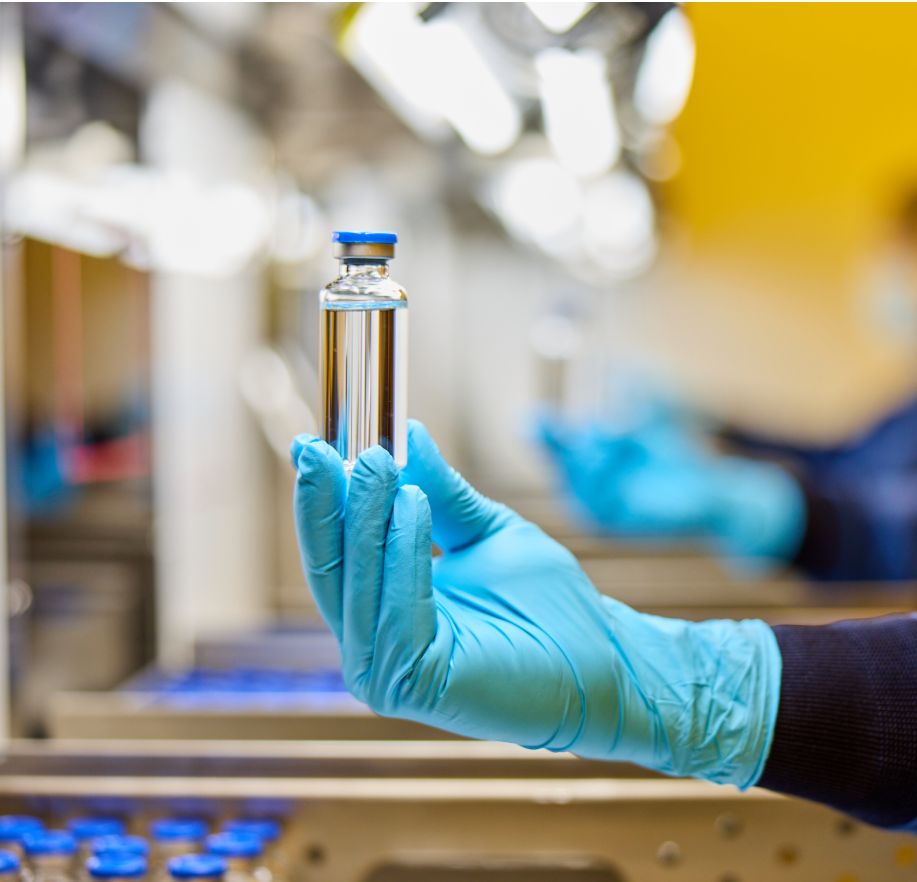

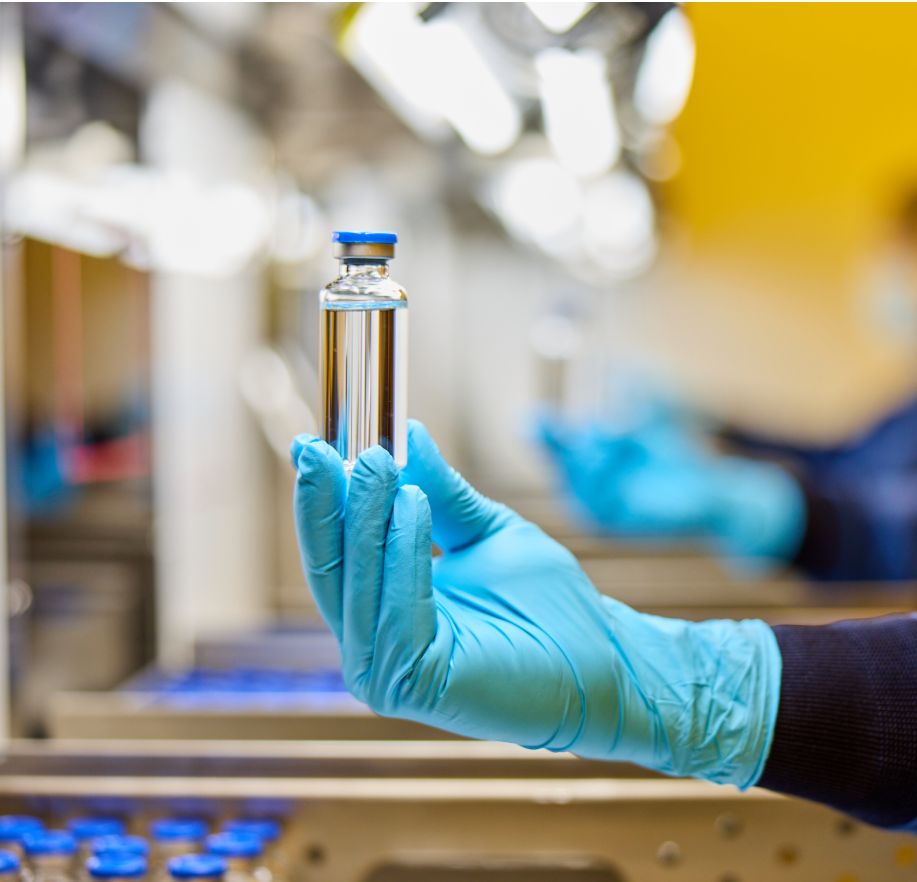

Sterility

Our commitment to precision involves employing the latest validated sterilization methods. We have strategically invested in highly efficient and advanced manufacturing equipment, including isolated sterile manufacturing lines equiped with vapor hydrogen peroxide systems, depyrogenation tunnels, ovens and autoclaves. This dedication to pharma scale technology underpins our mission to increase access to custom formulations for an ever-widening patient base.

Equipment

Specialized equipment leads to quality assurance and consistency in production. As an engineer-owned and led company, our first focus has always been on implementing automated systems and innovative technologies to streamline our processes and utilize economies of scale to keep drug costs low.

Quality Assurance

Striving to make our customer’s journey seamless and maintain our products’ consistency and quality, we incorporate a documented set of standards for quality at our compounding labs, designed in congruence with the FDA and the International Organization for Standardization. Every process is aligned with strategic directions, confirming and identifying raw materials before use, tracking and documenting at each stage along the manufacturing process.

Supporting your business operations through quality systems, scalability, and accessibility. Our 210,000 square feet of outsourcing facilities supply quality medication nationwide for pharmacies, hospitals, clinics and other healthcare businesses.

High Volume Production503B outsourcing facilities, where quality matters

503B outsourcing facilities produce custom medications in large batches for hospitals, medical offices, pharmacies, and other healthcare institutions. These medications, often referred to as "office-use medications," are administered by healthcare providers in hospitals or clinics. Additionally, these medications can be sold to pharmacies for patient dispensing.

Pharmaceutical compounding in outsourcing facilities utilizes advanced technology and quality systems to formulate, manufacture, and distribute custom medication efficiently.